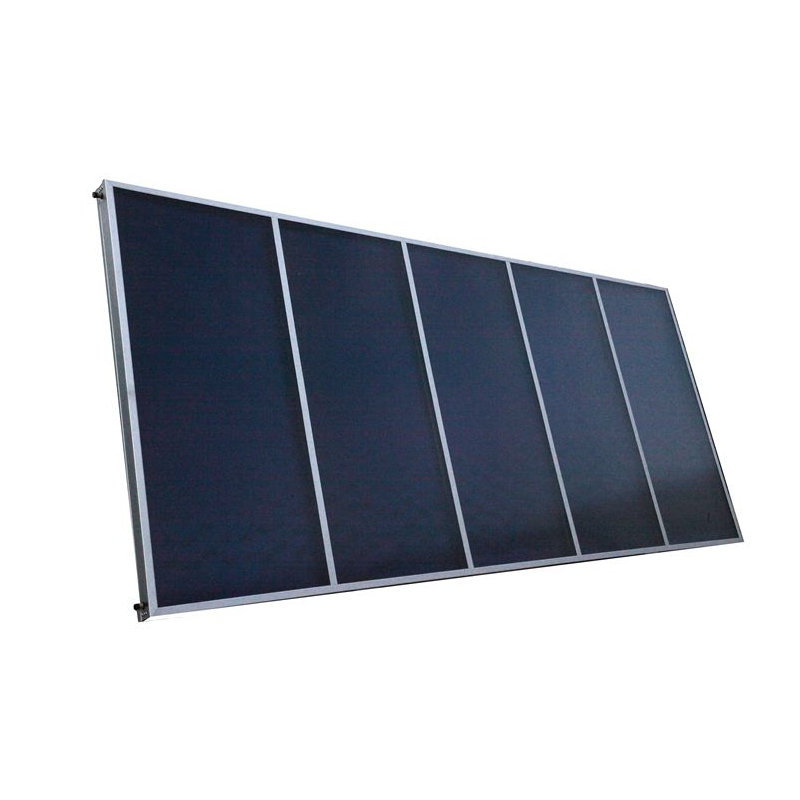

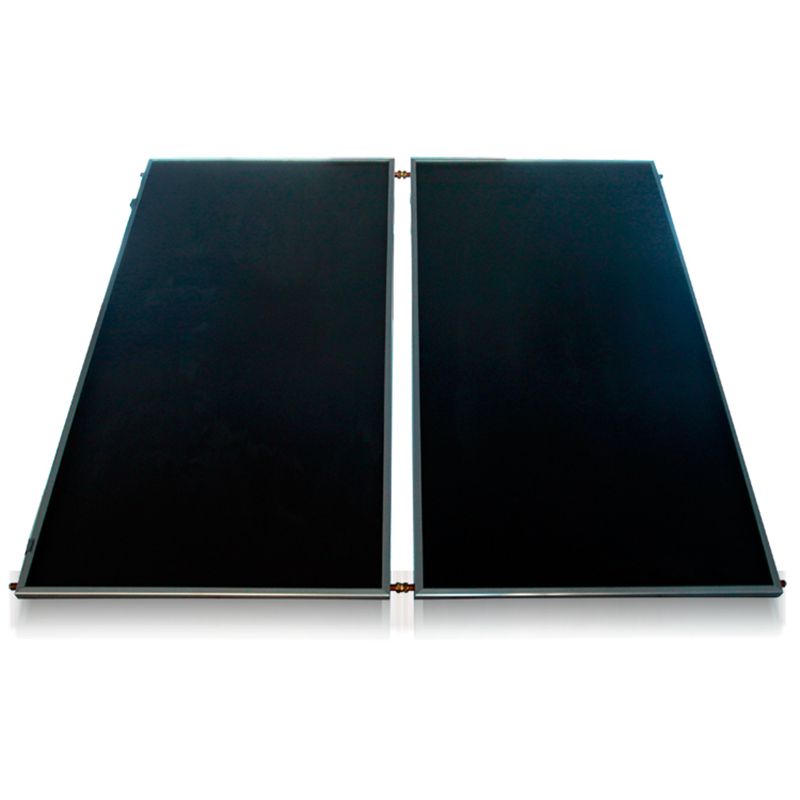

OEM Solar Collector

As innovative pioneers, the machines that we need for the production of our high-quality and market-conform solar products are not easily available “off the shelf”. Therefore, we constantly further develop our highly advanced machines with an “everything is possible” attitude, in order to enforce the diverse technical requirements. Aesthetic design and numerous environmental and innovation awards distinguish our collector families. Each individual collector range has numerous customer-specific designs. Hence, we are able to offer several hundred different types of collector variants and countless mounting solutions.

SPECIFICATION AND DATA:

Model No. & Specifications | BTE2.0-2 | BTE3.0-2 | |

Overall Data | Collector Dimension(mm) | 2000x1000x80 | 2000x1500x80 |

Overall Area (m2) | 2 | 3 | |

Aperture Area (m2) | 1.88 | 2.86 | |

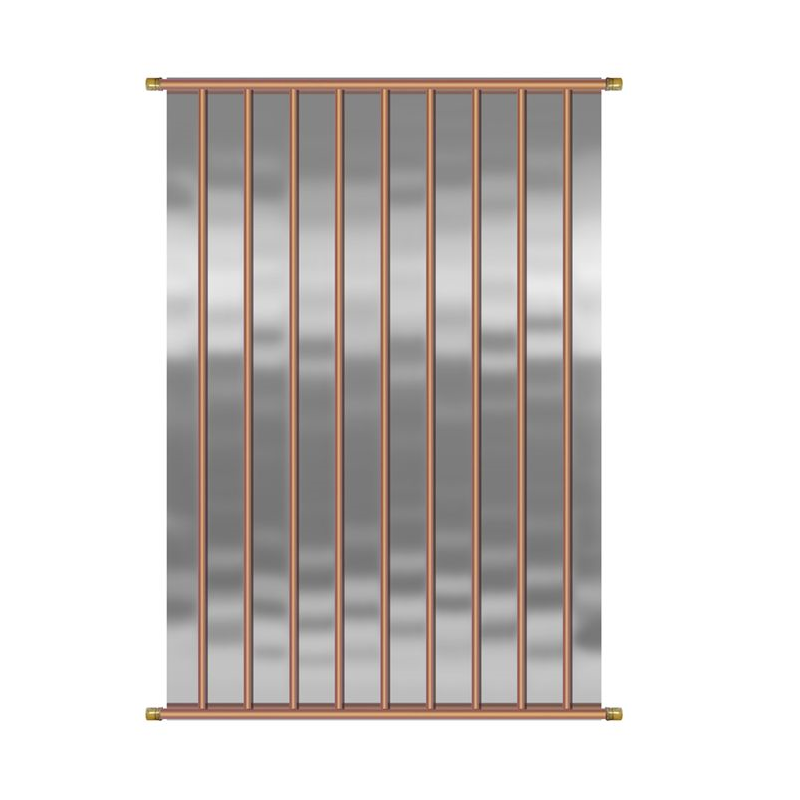

Absorber | Header Dimension(mm) | 22mmx0.6mm | 22mmx0.6mm |

Welding | Laser Welding | Laser Welding | |

Sheet | Al, High Selective Coated | Al, High Selective Coated | |

Riser Dimensions | 10mmx0.5mm | 10mmx0.5mm | |

Absorption | 95%(±2%@Am1.5) | 95%(±2%@Am1.5) | |

Emittance | 5%(±2%@80℃) | 5%(±2%@80℃) | |

Stagnation Temperature | 213℃ | 213℃ | |

Operating Pressure | 0.6 MPa | 0.6 MPa | |

Testing Pressure | 0.9 MPa | 0.9 MPa | |

Insulation | Insulation Material | Fiber Glass + Polyester Fiber | Fiber Glass + Polyester Fiber |

Insulation Thickness(mm) | Back: 30mm; Side: 20mm | Back: 30mm; Side: 20mm | |

Glazing | Transmittance | 91.50% | 91.50% |

Material | Tempered Solar Safety Glass | Tempered Solar Safety Glass | |

Casing | Frame | Aluminum 6063-T5 | Aluminum 6063-T5 |

Back Plate | Color Galvanized Plate, Thickness:0.5mm | Color Galvanized Plate, Thickness:0.5mm | |

Frame Color | Silver/Black | Silver/Black | |

Sealing Gasket | Integral Silicone Glue | Integral Silicone Glue | |

Conversion Factor Η0 | 0.778 | 0.778 | 0.778 |

Heat Transfer Coefficientα1 | 3.852W/(m2K) | 3.852W/(m2K) | 3.852W/(m2K) |

Temperature Dependent Heat Transfer Coefficientα2 | 0.008 W/(m2K2) | 0.008 W/(m2K2) | 0.008W/(m2K2) |

Overall Weight | Net Weight(kg) | 35 | 52 |

Load Qty | 40HQ Container | 350 PCS | 194PCS |

BTE BENEFITS:

1.The high quality and intelligent product design ensures unbeatable value for money

2.The robot-controlled production line ensures the highest levels of precision during the production process

3.Automatic production data acquisition and thereby traceability of each products’ raw material, producing date, producing worker, and delivery time easily and quickly

4.Three times quality check by 100% full-automatic pressure test in a closed cabin

5.The resistance and longevity of the welding seam with around 10048 welding spots per absorber is proven through accelerated ageing tests